Repair scheduling collisions pose significant challenges for automotive repair shops during peak seasons and complex projects due to overlapping appointments, resource constraints, and specialized requirements. Managers can mitigate these issues by proactively rescheduling, allocating resources, and hiring specialized staff. Robust quality control measures, including rigorous protocols and advanced tools, ensure every vehicle meets high standards. Efficient repair scheduling collision management using tailored software enhances quality control and customer satisfaction by streamlining processes, optimizing task allocation, and maximizing shop capacity for prompt, accurate repairs.

In the fast-paced world of automotive repairs, efficient repair scheduling is paramount to maintaining high quality control. However, collisions in scheduling – often due to conflicting appointments or resource constraints – can significantly hinder progress. This article delves into understanding common repair scheduling collisions and offers practical strategies for optimization. From implementing robust quality control measures to streamlining workflows, these techniques aim to enhance overall efficiency and ensure superior customer satisfaction.

- Understanding Common Repair Scheduling Collisions

- Implementing Effective Quality Control Measures

- Strategies to Streamline and Optimize Scheduling

Understanding Common Repair Scheduling Collisions

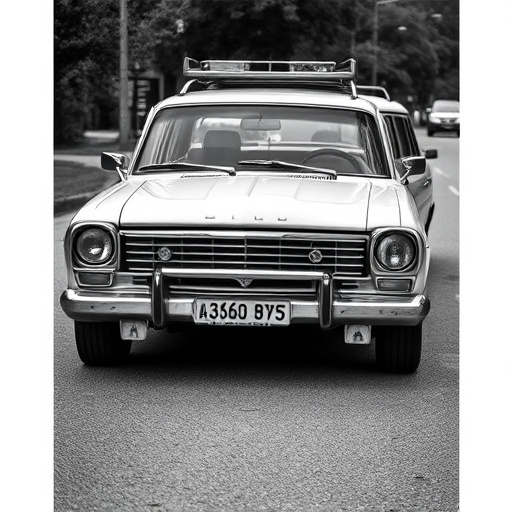

Repair scheduling collisions are a common challenge faced by automotive repair shops, especially during peak seasons or when dealing with complex car restoration projects. These conflicts arise due to various factors, such as overlapping service appointments, resource limitations, and the need for specialized equipment or skilled technicians. For instance, a vehicle needing extensive bodywork repair might require the same technician who is already booked for several other tasks, creating a collision in the schedule.

Understanding these collisions is the first step towards enhancing repair quality control. By identifying common triggers, such as high demand for specific services, limited available resources, or dependencies on particular technicians, shop managers can proactively address these issues. This may involve rescheduling appointments, allocating additional resources, or hiring specialized personnel to ensure that car restoration and automotive repair processes are not hindered by scheduling conflicts.

Implementing Effective Quality Control Measures

Implementing Effective Quality Control Measures is a pivotal step in any successful repair scheduling collision process. It involves establishing robust protocols to ensure that every vehicle undergoing restoration, whether it’s a meticulous fender repair or intricate vehicle paint repair, meets the highest standards. This includes regular inspections at every stage of the repair process, utilizing advanced tools and techniques to detect even the slightest imperfections.

By integrating these practices, repair shops can significantly enhance their control over the quality of work. It encourages a culture of precision and attention to detail, ultimately leading to superior vehicle restoration outcomes. Moreover, well-defined quality control measures foster better communication among team members, ensuring everyone is aligned in striving for excellence in every fender repair or vehicle paint repair task.

Strategies to Streamline and Optimize Scheduling

In the realm of collision repair, efficient scheduling is a game-changer that can significantly enhance overall quality control. One of the primary strategies to streamline and optimize this process is by implementing advanced software systems tailored for the automotive industry. These tools enable real-time tracking of vehicle arrivals, work in progress, and staff availability, minimizing delays and collisions (pun intended) in the repair process. By integrating such systems, collision repair shops can ensure a structured workflow, where each step is meticulously planned and executed.

Additionally, fostering open communication among team members can dramatically reduce scheduling conflicts. A well-informed schedule that considers the skill sets and capabilities of technicians allows for efficient task allocation. For instance, assigning complex tasks like fender repairs or intricate vehicle dent repair work to seasoned professionals ensures higher accuracy and faster turnaround times. This strategic approach not only optimizes the shop’s capacity but also guarantees customer satisfaction by delivering high-quality collision repair services promptly.

By understanding the root causes of repair scheduling collisions and implementing robust quality control measures, auto shops can significantly enhance their efficiency and customer satisfaction. Adopting strategic optimization techniques ensures a smoother workflow, minimizing delays and maximizing productivity. Embracing these practices is key to achieving superior repair results and maintaining a competitive edge in today’s automotive industry, where precise scheduling and quality are paramount.