Repair scheduling collision occurs when multiple jobs with similar resource needs compete for the same time slots in auto repair shops. This is common in bustling facilities serving diverse clients. Efficient scheduling is vital to prevent bottlenecks, streamline workflows, reduce costs, and speed up vehicle turnaround times, ultimately enhancing client satisfaction and shop competitiveness. Advanced systems integrating real-time data optimize collision management, reducing idle time, expediting repairs, and improving resource utilization.

In the fast-paced world of automotive services, efficient repair scheduling is paramount for business success. However, a common challenge arises from what’s often termed “repair scheduling collision”: concurrent or conflicting service requests. This article delves into the intricacies of this issue, exploring its profound impact on workflow efficiency and costs. We present strategic solutions to mitigate these collisions, optimizing processes to enhance customer satisfaction and boost operational productivity. Understanding and managing repair scheduling collision is a game-changer for any auto repair shop looking to stay competitive.

- Understanding Repair Scheduling Collision

- Impact on Workflow Efficiency and Costs

- Strategies to Mitigate and Optimize Collision Effects

Understanding Repair Scheduling Collision

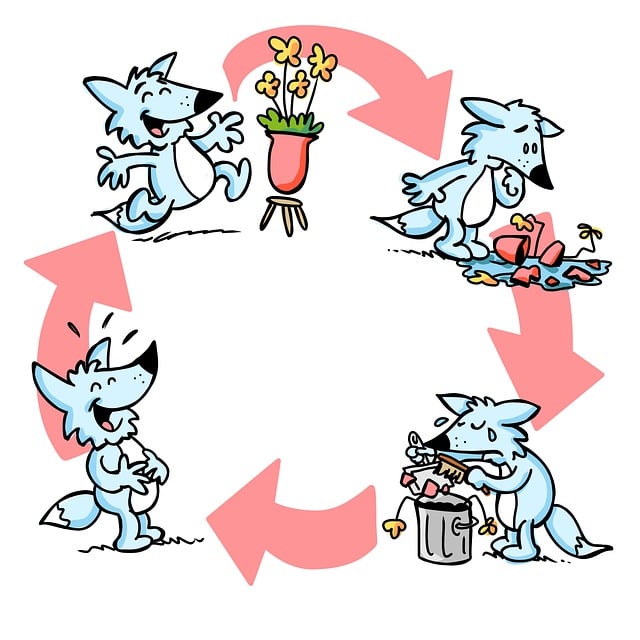

Repair scheduling collision refers to situations where multiple jobs requiring similar resources, such as specialized auto mechanics or specific equipment, compete for the same time slots in a repair shop’s schedule. This is particularly common in bustling automotive repair facilities that cater to a wide range of clients, from everyday vehicle owners to enthusiasts engaged in classic car restoration projects. Each job has its unique demands and timelines, making efficient scheduling crucial for workflow optimization.

In an automotive repair environment, understanding repair scheduling collision is essential to avoid bottlenecks and delays. Auto maintenance tasks often require specialized skills and tools, leading to a high level of resource dependency. For example, a classic car restoration project might necessitate the use of rare parts or intricate machinery that are only available for specific periods. Effective scheduling strategies must account for these dependencies to ensure jobs are completed promptly without interfering with other critical tasks.

Impact on Workflow Efficiency and Costs

The efficient management of repair scheduling collision is a key driver for enhancing workflow optimization within auto collision centers and scratch repair facilities. By effectively addressing these scheduling conflicts, businesses can substantially improve operational efficiency and reduce costs. When collision repairs are well-coordinated, technicians spend less time waiting for resources or materials, leading to faster turnaround times for customer vehicles. This not only boosts client satisfaction but also ensures that the auto collision center operates at its highest capacity without incurring excessive overhead.

Moreover, a streamlined repair scheduling process can significantly lower labor and material costs by minimizing unnecessary delays and redundant work. For instance, efficient scheduling can prevent situations where a technician starts a repair only to discover later that required parts or equipment are not readily available, reducing both wasted time and the need for additional labor. This holistic optimization approach is particularly beneficial for collision repair shops, contributing to their long-term sustainability and competitiveness in a market driven by swift service and quality outcomes.

Strategies to Mitigate and Optimize Collision Effects

In the realm of automotive maintenance, especially with luxury vehicle repair, minimizing collisions within a collision center is paramount to workflow optimization. Collision scheduling strategies often involve sophisticated systems that integrate real-time data from various sources like customer requests, vehicle drop-offs, and available technicians. This ensures that cars are allocated to workshops or bays efficiently, reducing idle time and maximizing resource utilization. By prioritizing urgent repairs and optimizing work flow, collision centers can provide faster turnaround times for car collision repair without compromising quality.

Moreover, leveraging technology such as advanced planning software and automated communication tools allows for proactive collision management. These systems enable staff to anticipate potential bottlenecks, reallocate resources swiftly, and keep customers informed throughout the process. This holistic approach not only mitigates collision-related disruptions but also enhances customer satisfaction in a bustling environment like a collision center, ultimately contributing to a seamless luxury vehicle repair experience.

Repair scheduling collision is a significant challenge in optimizing workflow efficiency, leading to increased costs and delays. By understanding the impact of these collisions and implementing strategies to mitigate them, organizations can streamline their operations and reduce overall expenses. Through effective collision management, businesses can enhance productivity, improve customer satisfaction, and ultimately achieve a more robust and responsive maintenance system. This data-driven approach ensures that repair schedules are optimized, resources are utilized efficiently, and workflow disruptions are minimized, making it an essential consideration for any modern maintenance strategy.